High molecular weight glutenin subunits and the classification used in Brazilian wheat industry

Received: June 06, 2017

Accepted: August 11, 2017

Published: September 21, 2017

Genet.Mol.Res. 16(3): gmr16039744

DOI: 10.4238/gmr16039744

Abstract

Industrial wheat quality flour is related to gluten amount in grain. This study aimed to evaluate the relationship between high molecular weight (HMW) glutenins obtained by SDS-PAGE and gluten strength (W) obtained by the alveograph test and cropping environmental effect on wheat flour quality for Brazilian industry. Fifty-one cultivars/breeding lines were evaluated in three environments. The W value and HMW glutenin score were evaluated by SDS-PAGE. The environment effects on wheat flour were also evaluated. There was a relationship between the W value used in wheat flour industrial classification and score 10 of HMW glutenins, but there was no relation with scores 9 or lower. Cultivars/breeding lines with score 10 of HMW glutenin are less susceptible to environmental effects and produce breeding type wheat flour (W value ≥300) of interest for industry. The cultivars/breeding lines with score 10 for HMW glutenins is the main choice for a wheat breeding program.

Introduction

Brazil is the twenty-second world producer of wheat (FAO - Food and Agriculture Organization of the United Nations, 2014) and, despite the oscillation, it has been growing mainly in the south of Brazil. Moreover, breeding programs have expanded the production of this grain for warmer regions with soil that has specific characteristics such as the Brazilian Cerrado (Santos, 2008). Wheat varieties are called soft or weak if gluten content or strength is low, and hard or strong if gluten content or strength is high. Wheat is classified into four types in Brazil, according to the flour quality: improver wheat, bread wheat, domestic wheat, and basic wheat (Brasil, 2010). The bread making and pasta industries have a demand for bread and improver wheat types, whereas the cracker industry demands the basic type. Flour classified as domestic wheat had lower commercial value and needed to be mixed with improver-type flours to be utilized in bread making (Guarienti, 1996).

The industrial quality of wheat is related to the amount and composition of gluten in the grain. Gluten is a composite of storage proteins termed prolamins, mainly low molar mass (LMM) gliadins and high molar mass (HMM) glutenins (Comino et al., 2013), referred to as low molecular weight (LMW) and high molecular weight (HMW), respectively (Lukow et al., 1988). Gluten attainable elasticity is proportional to its content of HMW glutenins (Lamacchia et al., 2014). Gluten has viscoelastic properties, and glutenin is the major protein within wheat flour, making up 47% of the total protein content (Belitz et al., 2004).

The production of these proteins is determined by genetic and environmental factors codified by seven genes Glu-A1, Glu-B1, and Glu-D1 located the long arm of the first homologous group of wheat genome (Lee et al., 2016). HMW proteins vary from 80,000 to 120,000 Da (Payne et al., 1979) and have the greatest responsibility for gluten elasticity to form high polymers, although they represent 25% of LMM proteins (Tatham et al., 1985; Gianibelli et al., 2001). There is an association of HMW protein subunits with the wheat flour industrial quality (Shewry et al., 2003; Anjum et al., 2007). The analyses of wheat flour quality association with HMW glutenin subunits are in general done by quantitative and correlation analyses (Torres et al., 2008). However, a regression analysis would be the most appropriate due to a dependent variable (gluten quality) and another independent variable (gluten composition). Furthermore, wheat cultivar classification concerning the industrial flour applications in Brazil is even more qualitative (breeding, bread, domestic, and basic types).

One of the main characteristics of wheat breeding is to develop grains with characteristics that meet the demands of the bread making, pasta, and cracker industries, and to avoid domestic wheat that has lower quality. However, in the initial phases of breeding, the available quantity of seeds is insufficient to determine the flour quality by rheological methods (Guarienti, 1996). On the other hand, the environmental effect on cropping can change wheat quality for bread making. Thus, the utilization of less susceptible cultivars to the environmental effect would be of great interest in the genetic breeding of wheat for the breadmaking industry in Brazil. Studies have not been found in the relationship of HMW glutenins with the industrial classification of wheat flour and the environmental effect on the expression of HMW glutenins. Thus, the objective of this study was to evaluate the relationship between HMW glutenins obtained by sodium dodecyl sulfate-polyacrylamide gel (SDS-PAGE) and the gluten strength obtained by the alveograph test, and the environmental effect of cultivation on wheat quality and the current wheat flour quality classification for Brazilian industry. The results can allow an early identification of wheat cultivars with a lower environmental effect on the flour quality.

Materials and Methods

MATERIAL AND METHODS

The experiments were carried out with seeds of 51 wheat cultivars/breeding lines from the genetic breeding program of COODETEC (Central Cooperative of Agricultural Research) in three different fields and periods. The first experimental field (EF1) was sown on 04/04/2007 and the second one (EF2) was sown on 04/20/2007, both located at the geographical coordinates of latitude 24°21'N, longitude 53°45' and altitude 320 m asl (Palotina-PR). The third experimental field (EF3) was sown on 05/23/2007 at the geographical coordination of latitude 41°24'N, longitude 2°10' and altitude 781 m asl (Cascavel-PR). The experimental fields had completely random blocks with three replicates. The study sample consisted of a bulk of seeds from the three replications for each treatment.

Gluten strength by the alveograph test

The alveograph test was used to measure the gluten strength (W) - or baking strength of dough - according to the American Association of Cereal Chemists (AACC 54.30-02) (AACC International, 2016). The alveograph test provides results that are common specifications used by flour millers and processors to ensure a more consistent process and product (WMCNAEGA, 2004). Wheat grain moist was determined and adjusted to 14.5% for grinding in the experimental Chopin grinder. For the bread-making process, 250 g wheat flour was mixed (1:1) with an aqueous solution of NaCl at 25 g/L. The dough was obtained by manual kneading for 6 min at an environmental temperature (25°C). After 30 min dough rest, the samples were placed in the alveograph at 25°C to determine W. The obtained wheat flour was classified according to the regulation number 38 of the Ministry of Agriculture, Livestock and Supply (Brasil, 2010), which classifies wheat flour between 100 and 160 W, as “basic” type (tipo básico, in Portuguese), between 160 and 219 W, as “domestic” type (tipo doméstico, in Portuguese), between 220 and 299 W, as “bread” type (tipo pão, in Portuguese), and equal to or higher than 300 W, as “improver” type (tipo melhorador, in Portuguese).

Glutenin extraction and analysis by SDS-PAGE

Glutenin extraction was done according to the protocol by Singh and Shepherd (1991). The grains (20 mg) were individually macerated and placed in 1.5-mL microtubes. For glutenin extraction, three solutions were utilized: solution A (50% isopropanol), solution B (50% isopropanol, 0.08 M Tris-HCl, pH 8.0) and solution C (20 g/L SDS, 400 g/L glycerol, 0.2 g/L bromophenol blue, 0.08 M Tris-HCl, pH 8.0). Solution A (1 mL) was added and incubated for 30 min at 65°C, and samples were agitated every 10 min. After this period, the samples were centrifuged at 10,000 g, for 1 min, and the supernatant was discarded. Next, 5 mL solution A was added to wash pellets and centrifuged for 5 min at 10,000 g. The supernatant was discarded after centrifugation. During centrifugation, solution B was prepared with 1% DTT (dithiothreitol), and 0.1 mL of this solution was added to the pellet. The microtube with the mixture was immersed in water at 65°C for 30 min. Then, centrifugation was carried out for 5 min at 10,000 g, and after it, 0.1 mL solution B was added with 1.4% 4-vinylpyridine to the sample, kept for 15 min again and centrifuged at 10,000 g for 1 min. The resulting supernatant, glutenin extract, was stored at 4°C until its utilization. Before electrophoresis, 0.1 mL glutenin extract was mixed with 0.1 mL solution C and immersed in water at 65°C for 15 min, followed by centrifugation for 1 min at 10,000 g. An aliquot of 20 μL supernatant was applied to SDS-PAGE for electrophoresis.

The piling gel consisted of 3.5% acrylamide, 0.12% bisacrylamide, 1% SDS, 0.1% ammonium persulfate, 0.126 M Tris [tris(hydroxyl methyl)amino methane] and 1% Temed (tetramethylethylenediamine). The separation gel contained 10% acrylamide, 0.3% bisacrylamide, 1% SDS, 0.1% ammonium persulfate, 0.375 M Tris, and 0.4% Temed. The loading buffer composition was 0.3% Tris, pH 8.3, 1.88% glycine, and 0.1% SDS. Electrophoresis was under a constant current of 100 V to the stacking gel and 120 V for the separation gel. In each gel, samples of control wheat cultivars were added: Sappo, Opata85, Chinese Spring, Neepawa, and Yacora-Rojo, which were extracted at the same way as the evaluated samples, and were considered reference for the identification of HMW glutenin bands. A score was attributed to each Glu-1 band, and the individual score for each variety/breeding line was obtained by the sum of individual scores of HMW subunits according to Payne (1987).

To evaluate the association between HMW glutenin subunits and wheat quality for bread making, a simple linear regression analysis was done. The qualitative association between the scores of HMW glutenins and wheat industrial classification (Brasil, 2010) was evaluated by contingency analysis. The significance of the contingency analysis was obtained by the chisquare test, and the analyses were performed using the GENES software (Cruz, 2006).

Results and Discussion

W values of 51 cultivars/breeding lines evaluated in three cropping environments and periods (EF1, EF2, and EF3) are shown in Table 1. The average W values varied from 164 to 396 in three environments (Table 1). Considering the average W values, 28% of the cultivars/breeding lines were classified as domestic type, 39% as bread type, and 33% as improver type (Table 1). These results suggest that the evaluated germplasm has great variability for W value and good industrial quality for bread making because 72% were classified as bread or breeding type.

| Cultivar/Breeding line | W value | Average (W) | CV (%) | HMW glutenin alleles | Cultivar/Breeding line score | |||||||

| EF1 | EF2 | EF3 | A1 | B1 | D1 | A1 | B1 | D1 | Total | |||

| CD654* | 363 | 374 | 452 | 396 | 12 | 2* | 9 | 5+10 | 3 | 2 | 4 | 9 |

| IPR85* | 415 | 415 | 317 | 382 | 15 | 1 | 7+8 | 5+10 | 3 | 3 | 4 | 10 |

| CD678 | 317 | 278 | 523 | 373 | 35 | 1 | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD111* | 323 | 372 | 404 | 366 | 11 | 1 | 7+8 | 5+10 | 3 | 3 | 4 | 10 |

| CD106* | 394 | 348 | 322 | 355 | 10 | 2* | 17+18 | 5+10 | 3 | 3 | 4 | 10 |

| CD706* | 371 | 362 | 329 | 354 | 6 | 2* | 17+18 | 5+10 | 3 | 3 | 4 | 10 |

| CD116* | 350 | 336 | 371 | 352 | 5 | 2* | 7+8 | 5+10 | 3 | 3 | 4 | 10 |

| CD108 | 282 | 309 | 417 | 336 | 21 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD705 | 348 | 367 | 288 | 334 | 12 | 2* | 6+8 | 5+10 | 3 | 1 | 4 | 8 |

| CD704 | 290 | 362 | 345 | 332 | 11 | 2* | 8 | 5+10 | 3 | 2 | 4 | 9 |

| CD677 | 284 | 365 | 325 | 325 | 12 | 2* | 17+18 | 5+10 | 3 | 3 | 4 | 10 |

| CD117 | 309 | 282 | 373 | 321 | 15 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD620 | 347 | 292 | 321 | 320 | 9 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD112 | 323 | 280 | 337 | 313 | 9 | 2* | 7+8 | 5+10 | 3 | 3 | 4 | 10 |

| CD515 | 342 | 305 | 279 | 309 | 10 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CDI702 | 281 | 352 | 286 | 306 | 13 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD710 | 294 | 270 | 342 | 302 | 12 | 2* | 8 | 5+10 | 3 | 2 | 4 | 9 |

| CD529 | 287 | 275 | 330 | 297 | 10 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD718 | 232 | 403 | 253 | 296 | 32 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD544 | 279 | 283 | 322 | 295 | 8 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD104** | 391 | 298 | 183 | 291 | 36 | 1 | 7+8 | 5+10 | 3 | 3 | 4 | 10 |

| CD647 | 274 | 302 | 289 | 288 | 5 | 2* | 8 | 5+10 | 3 | 2 | 4 | 9 |

| CD721 | 319 | 205 | 332 | 285 | 25 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD684 | 277 | 312 | 306 | 282 | 7 | N | 7 | 5+10 | 1 | 1 | 2 | 4 |

| CD646 | 247 | 282 | 303 | 277 | 10 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD548 | 308 | 255 | 260 | 274 | 11 | 1 | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD683* | 227 | 293 | 241 | 270 | 13 | 2* | 8 | 2+12 | 3 | 2 | 2 | 7 |

| CD114* | 280 | 246 | 278 | 268 | 7 | 1 | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| ONIX** | 113 | 285 | 400 | 266 | 54 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD558* | 274 | 236 | 265 | 258 | 8 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD711* | 286 | 235 | 226 | 249 | 13 | 1 | 8 | 5+10 | 3 | 2 | 4 | 9 |

| CD716 | 218 | 248 | 270 | 245 | 11 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD632 | 252 | 200 | 261 | 238 | 14 | 1 | 8 | 5+10 | 3 | 2 | 4 | 9 |

| CD610 | 272 | 241 | 201 | 238 | 15 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD715** | 220 | 303 | 180 | 234 | 27 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD712** | 300 | 253 | 146 | 233 | 34 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD619** | 179 | 194 | 300 | 224 | 29 | N | 6 | 2+12 | 1 | 1 | 2 | 4 |

| CD714 | 191 | 213 | 246 | 217 | 13 | 2* | 20 | 5+10 | 3 | 1 | 4 | 8 |

| CD110 | 243 | 140 | 261 | 215 | 30 | 1 | 7+8 | 2+12 | 3 | 3 | 2 | 8 |

| CD667 | 195 | 219 | 226 | 213 | 8 | N | 17+18 | 2+12 | 1 | 3 | 2 | 6 |

| CD631 | 220 | 220 | 186 | 209 | 9 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD649 | 202 | 257 | 167 | 209 | 22 | N | 9 | 2+12 | 1 | 2 | 2 | 5 |

| CD669 | 203 | 229 | 171 | 201 | 14 | N | 7+8 | 2+12 | 1 | 3 | 2 | 6 |

| CD651 | 168 | 235 | 197 | 200 | 17 | N | 7 | 5+10 | 1 | 1 | 4 | 6 |

| CD113* | 209 | 175 | 204 | 196 | 9 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD672 | 221 | 133 | 224 | 193 | 27 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD105* | 209 | 191 | 174 | 191 | 9 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CDI602* | 178 | 162 | 219 | 186 | 16 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD661** | 146 | 225 | 186 | 186 | 21 | 2* | 7 | 5+10 | 3 | 1 | 4 | 8 |

| CD627** | 132 | 171 | 222 | 175 | 26 | 2* | 7+9 | 5+10 | 3 | 2 | 4 | 9 |

| CD644 | 174 | 173 | 144 | 164 | 10 | 2* | 6+8 | 5+10 | 3 | 1 | 4 | 8 |

Table 1: Gluten strength (W) of 51 cultivars/breeding lines cultivated in three environments (experimental fields: EF1, EF2, EF3).

Considering the environment effect, 12 of the 51 samples were classified somehow regardless the cropping environment (Table 1). Seven samples presented three different classifications, one in each field (Table 1). These results illustrate how susceptible some cultivars/breeding lines are to the environment effect on wheat quality. Six of the 17 cultivars/ breeding lines, classified as improver type by the average of W values, kept this classification regardless of the environment (CD106, CD111, CD116, CD654, CD706, and IPR85), all with low variation coefficient (Table 1). Only four of 20 cultivars/breeding lines, classified as bread type, kept this classification regardless of the environment (CD114, CD558, CD683, and CD711), and only 3 of 14 cultivars/breeding lines, classified as domestic type, kept the same classification regardless of the environment (CD105, CD113, and CD602).

Choosing cultivars that are less affected by the environment effect for W value is fundamental to the availability of robust cultivars with a lower variation of the final obtained flour quality. The environmental factors at the harvest time affect the quality of flour. However, there is a great variation of results presented in these studies (Finlay et al., 2007; Uhlen et al., 2015). On the other hand, Georget et al. (2008) did not find differences between the proportion of HMW proteins when wheat breeding lines were evaluated in different environments but did not find differences when the interaction between the environment and genotype was assessed. These results suggest a greater complexity of determining factors of gluten composition. The results obtained in our study suggest that it had variability in the susceptibility to the environmental effect, and glutenin analysis were made to investigate if this variability was associated with HMW glutenin composition.

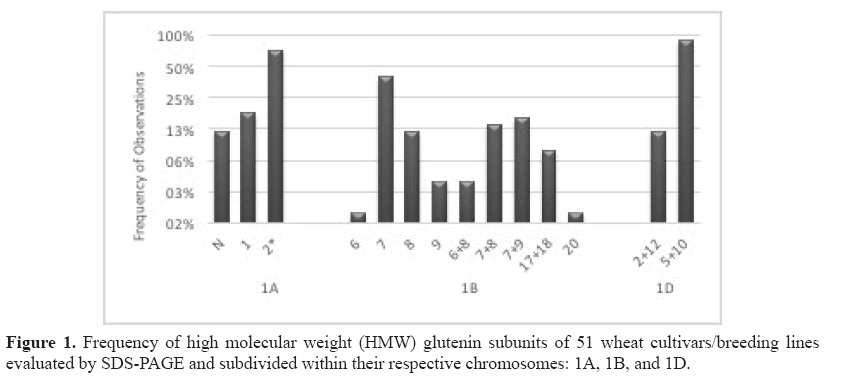

Table 1 shows the frequency distribution of HMW glutenin subunits of 51 cultivars/ breeding lines in which 14 subunits were found distributed between all wheat cultivars/breeding lines by SDS-PAGE. This variability is greater than the variability described by Argentinian breeding lines in which 11 subunits were found (Gianibelli et al., 2002). Figure 1 shows that on chromosome 1A, subunit 2* was the most frequent with approximately 70%, whereas the subunits 1 and null presented 18 and 12%, respectively. On chromosome 1B, there was a great variability of alleles and subunits 6, 9, 6+8, and 20 that were practically inexpressive. The sum of this unit represents 12%. On the other hand, subunits 8, 7+8, 7+9, and 17+18 had a frequency from 8 to 20%, while subunit 7 had a frequency of approximately 40%. On chromosome 1D, subunit 5+10 had 88% expression whereas subunit 2+12 had around 12%. Payne et al. (1987) reported that the presence of subunit 5+10 is associated with the high quality of wheat flour and subunit 2+12 is associated with low quality of wheat flour. This high incidence of subunits related to the high quality of wheat flour is explained by the Brazilian market that has a greater interest in bread-making flour. Thus, genotypes are selected according to the greater W values produced by the high incidence of alleles associated with this characteristic.

Torres et al. (2008) evaluated wheat cultivars utilized in the south of Brazil and observed a greater frequency of allele 2* (75%) on chromosome 1A. On chromosome 1D, allele 5+10 was found in 55% of the samples and allele 2+12 in 45% of them. Santos (2008) evaluated breeding wheat cultivars for the Brazilian Cerrado and observed a greater frequency of allele 2* (57%) and allele 1 with 43% on chromosome 1A. On chromosome 1B, the greatest frequency was in alleles 7+9 and 7+8 with 43% each. Alleles 5+10 and 2+12 presented 71 and 29% frequencies, respectively, for chromosome 1D. These studies made evident that these alleles are distributed and well-characterized in genotypes of Brazilian wheat, corroborating the results of allele frequency found in our study.

Each one of the 51 cultivars/breeding lines evaluated in our study received a score in function of its composition of HMW glutenins, calculated by the sum of individual scores of each subunit, according to Payne (1987). The scores in our study varied from 4 to 10, and the most frequent were 8 (43%). Only 14% obtained a score lower than 8 (Table 1 and Figure 1), and the general average was established at 8.23. Several studies reported the correlation of high values of HMW glutenin scores with the high quality of wheat flour (Payne, 1987; Schuster et al., 1997; Gianibelli et al., 2001, 2002). Gianibelli et al. (2002) obtained an average score of 9.3 in Argentinian cultivars whereas Lukow et al. (1988) had an average of 8.74 in Canadian cultivars. Santos (2008) had a score of 8.4 in Brazilian wheat cultivar in 2008, making evident the positive results in the genetic breeding of Brazilian wheat compared to the score of 7.62 in 2004 (Silva et al., 2004). This makes an apparent increase in Brazilian wheat quality along time concerning the genetic material cultivation worldwide.

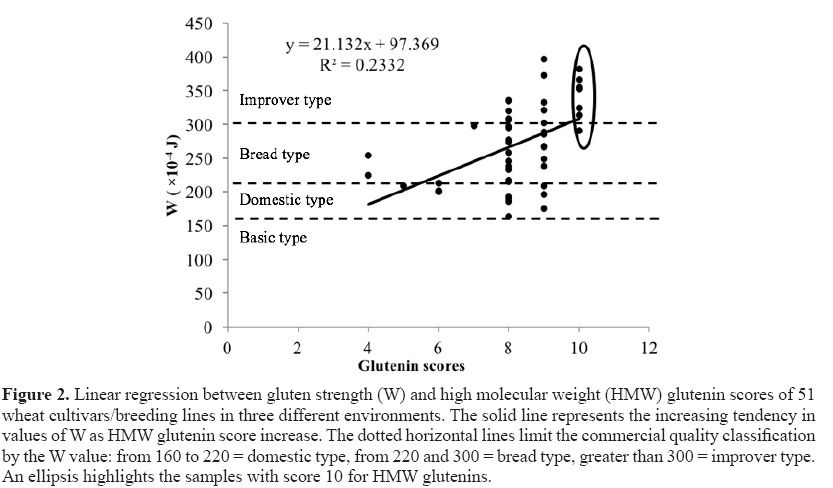

The linear regression between the W value and HMW glutenin score showed a significant association (R2 = 0.23, P = 0.03). When compared with the current commercial classification, cultivars/breeding lines with scores 8 and 9 were classified as domestic and improver types whereas the ones with score 10 were classified as improver type except for one that was classified as bread type (Figure 2). Five of six cultivars/breeding lines classified as improver type in three environments scored 10, and the other scored 9 (Table 1). These results suggest that score 10 of HMW glutenins is associated with a wheat cultivar that has a greater aptitude for bread making or improving the quality of poor flour, that is, score 10 means improver type. Also, cultivars/breeding lines with score 10 of HMW glutenins presented greater stability in the production of improver type and smaller susceptibility to the environmental effect of this characteristic when cultivated in different environments. The association of wheat quality with cultivars/breeding lines with score 10 of HMW glutenins allows genetic analyses to be developed with HMW glutenin expression to establish new genetic breeding strategies of wheat quality for bread making in a shorter time.

Figure 2: Linear regression between gluten strength (W) and high molecular weight (HMW) glutenin scores of 51 wheat cultivars/breeding lines in three different environments. The solid line represents the increasing tendency in values of W as HMW glutenin score increase. The dotted horizontal lines limit the commercial quality classification by the W value: from 160 to 220 = domestic type, from 220 and 300 = bread type, greater than 300 = improver type. An ellipsis highlights the samples with score 10 for HMW glutenins.

To verify if the aptitude related to the bread-making quality of wheat is associated with score 10 of HMW glutenins, the samples were divided into two groups in function of their scores: a group with score 10 and another group with score 9 or lower. The samples were also divided into three groups in function of W values: one group with W values lower than 220 (domestic type), one group with W values from 220 to 300 (bread type), and one group with W values greater than 300 (improver type) (Table 2). The independence test between the groups was significant (χ2 = 12.68; P = 0.00176), indicating that the samples with score 10 are classified differently from the samples with score 9 or lower (Table 2). The same happens when the samples are divided into two groups in function of the values of W: a group with improver-type samples (W greater than 300) and another group with samples that are not classified as improver type (W lower than 300). The independence test was also significant (χ2 = 13.88, P = 0.00019). However, when the sample was divided into domestic-type groups (W lower than 220) and bread/improver type (W greater than 220), the independence test between the groups was not significant (χ2 = 3.59, P = 0.0581), showing that this kind of grouping of quality type is independent of glutenin score. Therefore, these results indicate that the cultivars/breeding lines that present score 10 are equivalent to the classification of

| W values (x10-4 J) | ||||

| Score | <220 | 220 to 300 | >300 | Total |

| <10 | 14 | 19 | 10 | 43 |

| 10 | 0 | 1 | 7 | 8 |

| Total | 14 | 20 | 17 | 51 |

| χ2 = 12.68%; d.f. = 2; P = 0.00176. | ||||

| W values (x10-4 J) | ||||

| Score | <300 | >300 | Total | |

| <10 | 34 | 9 | 43 | |

| 10 | 1 | 7 | 8 | |

| Total | 35 | 16 | 51 | |

| χ2 = 13.88%; d.f. = 1; P = 0.00019. | ||||

| W values (x10-4 J) | ||||

| Score | <200 | >200 | Total | |

| <10 | 14 | 29 | 43 | |

| 10 | 0 | 8 | 8 | |

| Total | 14 | 37 | 51 | |

| χ2 = 3.59%; d.f. = 1; P = 0.00581. | ||||

d.f. = degrees of freedom. The analysis considered two groups of samples: score 10 and score 9 or lower.

Table 2: Contingency analysis between the high molecular weight (HMW) glutenin scores and gluten strength (W).

improver type (W greater than 300).

However, to evaluate if this same dependence also occurs with scores lower than 10, the samples were again divided into two groups in function of the score: one group with samples whose score is 9 and another with samples whose score is 8 or lower, not considering in this analysis the samples with score 10 (Figure 2). As a result, no dependence between the groups was observed (Table 3), showing once again that the dependence is in the samples with score 10 and improver type.

| W values (x10-4 J) | ||||

Score |

<220 | 220 to 300 | >300 | Total |

| <9 | 11 | 13 | 5 | 29 |

| 9 | 3 | 6 | 5 | 14 |

| Total | 14 | 19 | 10 | 43 |

| χ2 = 2.18%; d.f. = 2; P = 0.3356. | ||||

| W values (x10-4 J) | ||||

Score |

<300 | >300 | Total | |

| <9 | 29 | 5 | 29 | |

| 9 | 4 | 5 | 14 | |

| Total | 33 | 10 | 43 | |

| χ2 = 1.80%; d.f. = 1; P = 0.1791. | ||||

| W values (x10-4 J) | ||||

| Score | <200 | >200 | Total | |

| <9 | 11 | 18 | 29 | |

| 9 | 3 | 11 | 14 | |

| Total | 14 | 29 | 43 | |

| χ2 = 1.171%; d.f. = 1; P = 0.2792. | ||||

d.f. = degrees of freedom. The analysis considered two groups of samples: score 9 and score 8 or lower, and regardless the ones with scores 10.

Table 3: Contingency analysis between high molecular weight (HMW) glutenin scores and gluten strength (W).

This study made evident for the first time a relationship between HMW glutenins and the classification of wheat cultivars according to their commercial utilization aptitude. This is a new approach to the relationship between HMW glutenins and bread-making wheat quality that is better applied to commercial wheat breeding. All the previous research in HMW glutenins was made associating quantitatively the scores of HMW glutenins and W value, regardless the industrial classification of wheat quality.

Conclusion

It was concluded that there is a relationship between the commercial class of improvertype wheat flour and score 10 of HMW glutenins obtained by SDS-PAGE, but there is no relationship with scores 9 or lower.

Cultivars/breeding lines with score 10 of HMW glutenins produced improver-type wheat flour (W value higher than 300) and are robust, less susceptible to the environmental effect of the harvest time, and produce wheat with greater quality and interest for the wheat flour industry.

Acknowledgments

The authors thank the Paranaense University, the Postgraduate Program in Biotechnology Applied to Agriculture, Cooperativa Central de Pesquisa Agrícola, Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), and Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) for the fellowship and financial support.

About the Authors

Corresponding Author

G.J. Silva

Programa de Pós-Graduação em Biotecnologia Aplicada à Agricultura, Laboratório de Biologia Molecular, Universidade Paranaense, Umuarama, PR, Brasil

References

- AACC International (2016). American Association of Cereal Chemists. Approved Methods of Analysis. 11th edn. Method 54-30.02. Alveograph Method for Soft and Hard Wheat Flour. AACC International, St. Paul.

- Anjum FM, Khan MR, Din A, Saeed M, et al. (2007). Wheat gluten: high molecular weight glutenin subunits - structure, genetics, and relation to dough elasticity. J. Food Sci. 72: R56-R63. https://doi.org/10.1111/j.1750-3841.2007.00292.x

- Belitz HD, Grosch W and Schieberle P (2004). Food Chemistry. 4th edn. Springer, Heidelberg.

- Brasil (2010). Ministério da Agricultura, Pecuária e Abastecimento. Instrução Normativa nº 38, de 30 de novembro de 2010. Regulamento técnico do trigo. Diário Oficial [da] República Federativa do Brasil, Brasília DF, n. 29, p. 2, 1 dez. 2010. Seção 1. Available at [http://www.agricultura.gov.br/].

- Comino I, Moreno MdeL, Real A, Rodríguez-Herrera A, et al. (2013). The gluten-free diet: testing alternative cereals tolerated by celiac patients. Nutrients 5: 4250-4268. https://doi.org/10.3390/nu5104250

- Cruz CD (2006). Programa Genes - Estatística experimental e matriz. UFV, Viçosa.

- FAO - Food and Agriculture Organization of the United Nations (2014). FAOSTAT Database. Rome, Italy. Retrieved in: 28 Oct. 2014.

- Finlay GJ, Bullock PR, Sapirstein HD, Naeem HA, et al. (2007). Genotypic and environmental variation in grain, flour, dough and bread-making characteristics of western Canadian spring wheat. Can. J. Plant Sci. 87: 679-690. https:// doi.org/10.4141/P06-150

- Georget DMR, Underwood-Toscano C, Powers SJ, Shewry PR, et al. (2008). Effect of variety and environmental factors on gluten proteins: an analytical, spectroscopic, and rheological study. J. Agric. Food Chem. 56: 1172-1179. https:// doi.org/10.1021/jf072443t

- Gianibelli MC, Larroque OR, Mac-Ritchie F and Wrigley CW (2001). Biochemical, genetic and molecular characterization of wheat gluten and its component subunits. Cereal Chem. 78: 635-646. https://doi.org/10.1094/ CCHEM.2001.78.6.635

- Gianibelli MC, Echaide M, Larroque OR, Carrillo JM, et al. (2002). Biochemical and molecular characterisation of Glu-1 loci in Argentinean wheat cultivars. Euphytica 128: 61-73. https://doi.org/10.1023/A:1020643702867

- Guarienti EM (1996). Qualidade industrial de trigo. Embrapa, Passo Fundo.

- Lamacchia C, Camarca A, Picascia S, Di Luccia A, et al. (2014). Cereal-based gluten-free food: how to reconcile nutritional and technological properties of wheat proteins with safety for celiac disease patients. Nutrients 6: 575-590. https:// doi.org/10.3390/nu6020575

- Lee JY, Beom HR, Altenbach SB, Lim SH, et al. (2016). Comprehensive identification of LMW-GS genes and their protein products in a common wheat variety. Funct. Integr. Genomics 16: 269-279. https://doi.org/10.1007/s10142-016-0482-3

- Lukow OM, Paynes PI and Tkachukl R (1988). The HMW glutenin subunit composition of Canadian wheat cultivars and their association with bread-making quality. J. Sci. Food Agric. 46: 451-460. https://doi.org/10.1002/jsfa.2740460407

- Payne PI (1987). Genetics of wheat storage proteins and the effect of allelic variation on bread-making quality. Annu. Rev.Plant Physiol. 38: 141-153.https://doi.org/10.1146/annurev.pp.38.060187.001041

- Payne PI, Corfield KG and Blackman JA (1979). Identification of a high-molecular-weight subunit of glutenin whose presence correlates with bread-making quality in wheats of related pedigree. Theor. Appl. Genet. 55: 153-159. https:// doi.org/10.1007/BF00295442

- Payne PI, Nightingale MA, Krattiger AF and Holt LM (1987). The relationship between HMW glutenin subunit composition and the bread-making quality of British-grown wheat varieties. J. Sci. Food Agric. 40: 51-65. https:// doi.org/10.1002/jsfa.2740400108

- Santos LS (2008). Perfil proteico e qualidade de panificação em linhagens de trigo desenvolvidas para a região do cerrado brasileiro. Dissertação de Mestrado - Universidade Federal de Viçosa, Viçosa. Available at [http://locus.ufv.br/ bitstream/handle/123456789/2831/texto completo.pdf?sequence=1&isAllowed=y].

- Schuster I, Souza MA, Cardoso AM, Sediyama CS, et al. (1997). Correlation between high molecular weight gluten subunits composition and bread making quality in Brazilian wheat. Braz. J. Genet 20: 667-671. https://doi. org/10.1590/S0100-84551997000400019

- Shewry PR, Halford NG, Tatham AS, Popineau Y, et al. (2003). The high molecular weight subunits of wheat glutenin and their role in determining wheat processing properties. Adv. Food Nutr. Res. 45: 219-302. https://doi.org/10.1016/ S1043-4526(03)45006-7

- Silva SA, Carvalho FIF, Nedel JL, Vasconcellos NJS, et al. (2004). High molecular weight glutenin (HMW) subunits in stay-green trait in wheats. Cienc. Rural 34: 679-683. https://doi.org/10.1590/S0103-84782004000300005

- Singh NK and Shepherd KW (1991). Cornish GB, Simplified SDS-PAGE procedure for separating LMW subunits of glutenin. Cereal Res. Commun. 14: 203-208.

- Tatham AS, Miflin BJ and Shewry PR (1985). The beta-turn conformation in wheat gluten proteins: relationship to gluten elasticity. Cereal Chem. 62: 405-442.

- Torres GAM, Miranda MZ, Nicolau M, Consoli L, et al. (2008). Estudos preliminares da associação de gluteninas de alto peso molecular e parâmetros de qualidade tecnológica de trigo. Embrapa, Passo Fundo.

- Uhlen AK, Dieseth JA, Koga S, Boecker U, et al. (2015). Variation in gluten quality parameters of spring wheat varieties of different origin grown in contrasting environments. J. Cereal Sci. 62: 110-116. https://doi.org/10.1016/j. jcs.2015.01.004

- WMC-NAEGA (2004). Wheat and flour testing methods: a guide to understanding wheat and flour quality. Wheat Marketing Center Inc., Portland.

Keywords:

Download:

Full PDF- Share This